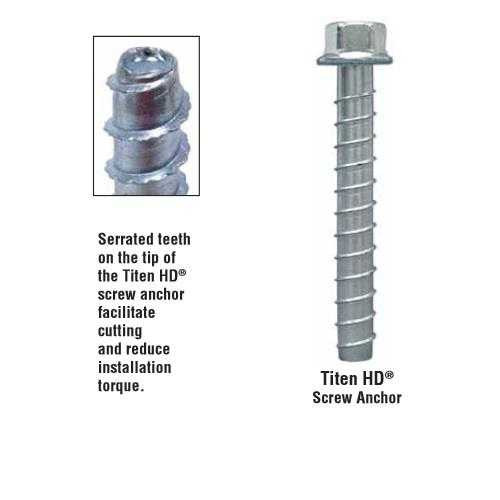

Product Description

A high-strength screw anchor for use in cracked and uncracked concrete, as well as uncracked masonry. The Titen HD offers low installation torque and outstanding performance. Designed for use in dry, interior, non-corrosive environments or temporary outdoor applications.

The stainless-steel Titen HD is the optimal choice for applications in corrosive or extreme environments such as salt water, or when chemical or corrosive solutions are present. See Stainless-Steel Titen HD for more information.

Key Features

- Tested in accordance with ACI 355.2, AC193 and AC106

- Qualified for static and seismic loading conditions

- Thread design undercuts to efficiently transfer the load to the base material

- Standard fractional sizes

- Specialized heat-treating process creates tip hardness for better cutting without compromising the ductility

- No special drill bit required — designed to install using standard-sized ANSI tolerance drill bits

- Hex-washer head requires no separate washer, unless required by code, and provides a clean installed appearance

- Removable — ideal for temporary anchoring (e.g., formwork, bracing) or applications where fixtures may need to be moved

- Reuse of the anchor will not achieve listed loads and is not recommended

Material

- Carbon steel

Finish

- Zinc plated or mechanically galvanized

- Not recommended for permanent exterior use or highly corrosive environments

Installation

- Drill a hole in the base material using a carbide drill bit the same diameter as the nominal diameter of the anchor to be installed. Drill the hole to the specified embedment depth plus minimum hole depth overdrill (see table below) to allow the thread tapping dust to settle, and blow it clean using compressed air. (Overhead installations need not be blown clean.) Alternatively, drill the hole deep enough to accommodate embedment depth and the dust from drilling and tapping.

- Insert the anchor through the fixture and into the hole.

- Tighten the anchor into the base material until the hex-washer head contacts the fixture.

| Titen HD Diameter (in.) | Wrench Size (in.) | Recommended Fixture Hole Size (in.) | Min. Hole Depth Overdrill (in.) |

|---|---|---|---|

| Suggested fixture hole sizes are for structural steel thicker than 12 gauge only. Larger holes are not required for wood or thinner cold-formed steel members. | |||

| 1/4 | 3/8 | 3/8 to 7/16 | 1/8 |

| 3/8 | 9/16 | 1/2 to 9/16 | 1/4 |

| 1/2 | 3/4 | 5/8 to 11/16 | 1/2 |

| 5/8 | 15/16 | 3/4 to 13/16 | 1/2 |

| 3/4 | 1 1/8 | 7/8 to 15/16 | 1/2 |

Caution

- Holes in metal fixtures to be mounted should match the diameter specified in the table below.

- Use a Titen HD screw anchor one time only — installing the anchor multiple times may result in excessive thread wear and reduce load capacity.

- Do not use impact wrenches to install into hollow CMU.

- Oversized holes in base material will reduce or eliminate the mechanical interlock of the threads with the base material and reduce the anchor’s load capacity.

Please Note: This product image may represent a range of products; it may not be an exact representation of the product purchased.